At Fuji Electric we develop products that maximize energy efficiency and lead to a responsible and sustainable society

Earthing system

In an electrical installation or an electricity supply system, an earthing system or grounding system connects specific parts of that installation with the Earth’s conductive surface for safety and functional purposes.

Earthing: is the connection of the exposed conductive parts of the installation by means of

protective conductors to the “main earthing terminal”, which is connected to an electrode in contact with the earth’s surface.

A protective earthing conductor (PE): avoids electric shock hazard by keeping the exposed-conductive surface of connected devices close to earth potential in fault conditions. In the event of a fault, a current is allowed to flow to earth by the earthing system. If this is excessive the overcurrent protection of a fuse or circuit breaker will operate, thereby protecting the circuit and removing any fault induced voltages from the exposed-conductive surfaces.

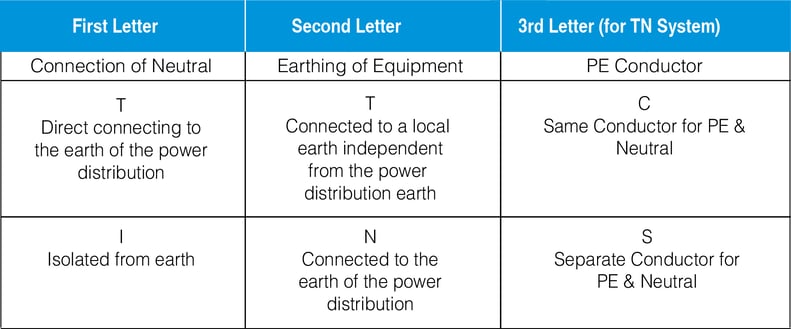

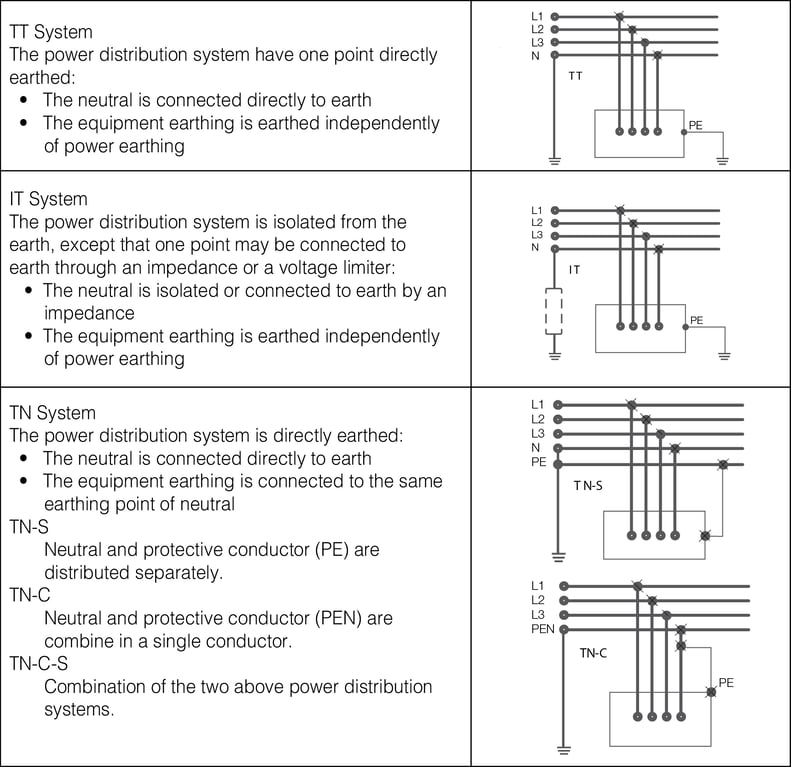

A functional earth: connection serves a purpose other than electrical safety, and may carry current as a part of normal operation. The most important example of a functional earth is the neutral in an electrical supply system when it is a current-carrying conductor connected to the earth electrode at the source of electrical power. International standard IEC 60364/ IS 3043 distinguishes three families of earth arrangements using the two letter codes TN, TT, and IT (three letter codes only for TN systems)

Types of Earthing System

Earthing principles of UPS system

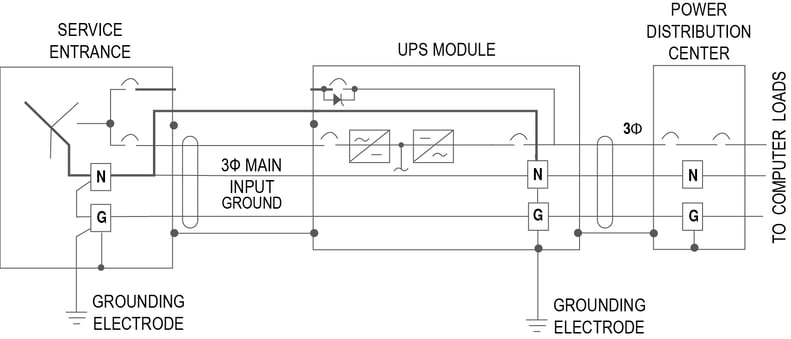

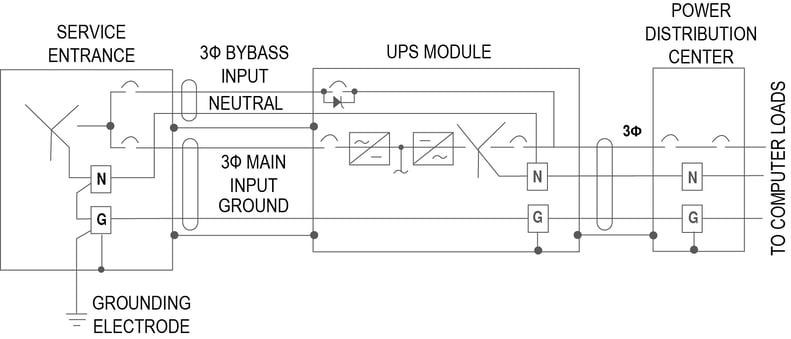

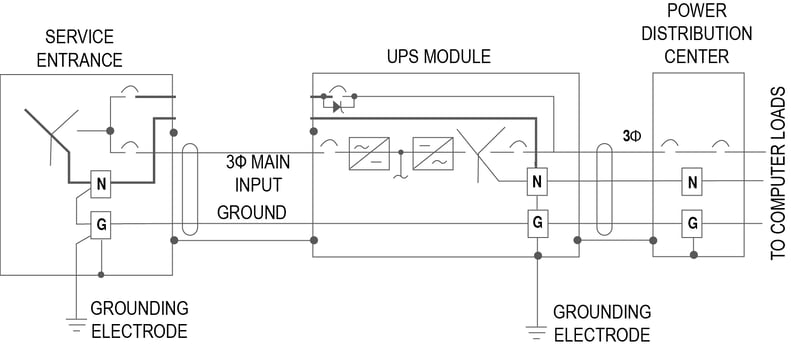

Transformer-based/transformerless UPS with bypass

In this system Figure 1, the UPS Neutral Should not be bonded to the grounding conductor. This earthing configuration is similar for both transformer based / transformer less UPS and

- Does not change the upstream and downstream earthing system

- Does not provide any galvanic Isolation or

- Does not provide Common Mode Noise attenuation.

Figure 3 Transformerless UPS Without Bypass

Transformer-based UPS without bypass

In this system Figure 1, the UPS neutral should be bonded to the grounding conductor.

This earthing configuration

- Change’s the upstream and downstream earthing system

- Provides galvanic Isolation

- Provides Common Mode Noise attenuation.

Figure 1 Earthing System- UPS With bypass

Transformerless UPS without bypass

In this system Figure 3, the UPS neutral should not be bonded to the grounding

conductor. This earthing configuration is similar for both transformer based / transformerless UPS with bypass and

- Does not change the upstream and downstream earthing system

- Does not provide any galvanic isolation or

- Does not provide Common Mode Noise attenuation.

Figure 2 Transformer Based UPS Without Bypass

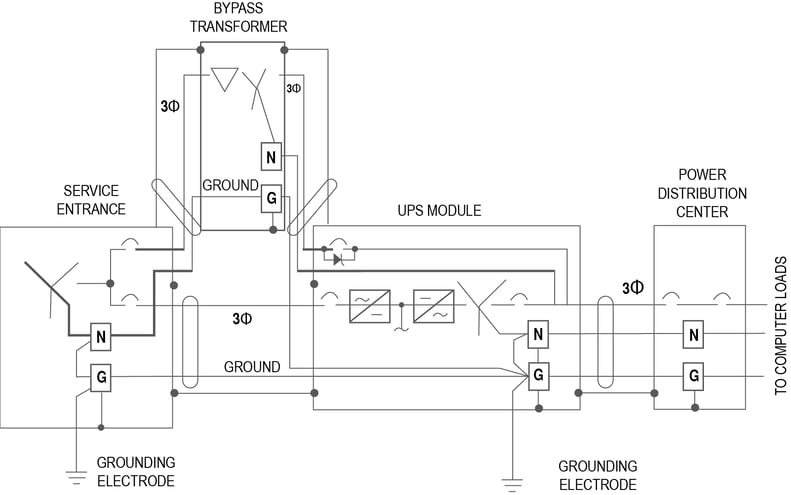

UPS with Isolated bypass

In this system Figure 4, a transformer is introduced in the bypass path of the UPS. The

output neutral of the UPS should be bonded to the grounding conductor. The UPS acts as a seperatively drived source. This earthing configuration

- Change’s the upstream and downstream earthing system

- Provides galvanic Isolation

- Provides Common Mode Noise attenuation.

Points to be taken care while earthing UPS

• Using of 4 Pole breakers at the input is prohibited as it breaks the input neutral which results in the floating of output neutral

• The output neutral of the UPS should not be earthed unless there is a transformer in the bypass or global input.

• The bypass mains and the rectifier mains has to be supplied with power from the same earthing system. If the earthing systems are different a transformer needs to be considered in bypass or rectifier input.

• In TNS system, the neutral earthing should be done only at one point(at source) only, multiple earthing is prohibited as per standards.

Figure 4 UPS with isolated bypass

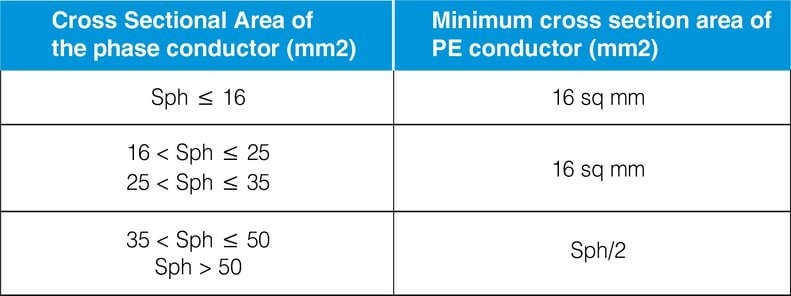

Selecting the earthing conductor size

Please see below the Earthing conductor size requirement. This is based on the standard IEC 60364-5-54

China

China Europe

Europe France

France Hong Kong

Hong Kong Indonesia

Indonesia Japan

Japan Singapore

Singapore Thailand

Thailand USA

USA