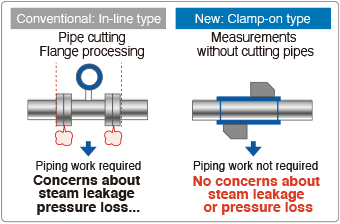

No plumbing required

Installable with no pipe cutting or flange processing. Installable without stopping production lines and no steam leakage concerns since plumbing is not required.

Less maintenance cost

No moving parts help to reduce regular maintenance costs such as cleaning.

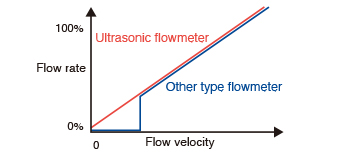

Enables measurements at low flow rates

The ultrasonic flowmeter can meusure at low flow rate, even at flow rates of 0.

Convertible to mass flow rate

The measured volume flow measurement and density (fixed value) input can be converted to mass flow rate and output. Density correction can also be performed by measuring the pressure (4 to 20 mA DC) and temperature (with resistance bulb) of the saturated steam and inputting as external signal (AI).

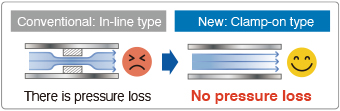

No pressure loss

The ultrasonic sensors do not interfere with the steam flow.

China

China Europe

Europe France

France Hong Kong

Hong Kong Indonesia

Indonesia Japan

Japan Singapore

Singapore Thailand

Thailand USA

USA

.jpg)