At Fuji Electric we develop products that maximize energy efficiency and lead to a responsible and sustainable society

Servo Controlled Voltage Stabilizer

The absence of stable voltage in the power supply can cause breakdown of sensitive electronic equipment and thereby impact the business continuity. Low voltage electric power distribution is 230 volts for single phase and 415 volts for three-phase. In such case, all electrical appliances (especially, single phase) are designed to operate in the voltage range of 220 to 240V.

The acceptable range of voltage in some countries (also in India) is 230 ± 10V as per the electricity standards. And also, many appliances can withstand this voltage fluctuation range. But in most places, voltage fluctuations are quite common and typically, they are in the range of 170 to 270V. These voltage fluctuations can have significant adverse effects on appliances.

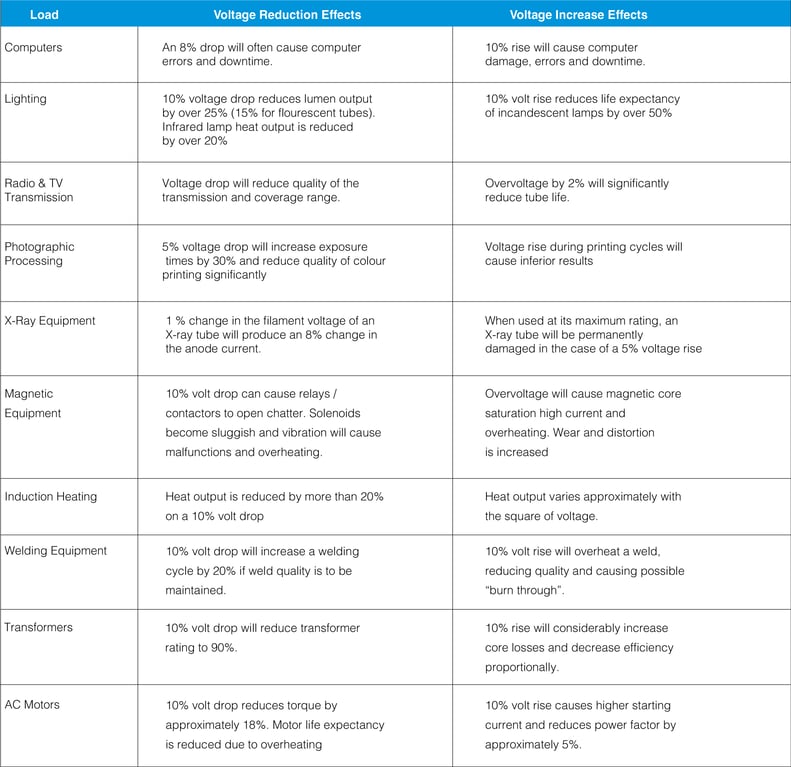

Impact of voltage variations on equipments

• In case of all electronic equipments failure rate increases at higher voltages.

• In case of lighting equipment, low voltage reduces the lumen output (illumination) that will further reduce the life of the lamp.

• AC motor produces less torque and hence the speed reduces under low voltage, and they produce more speed than desired during overvoltage. This degrades motor life and also causes insulation damage under high voltages.

• In case of induction heating, low voltage reduces heat output, which causes the load to operate at inappropriate temperatures than desired.

• In TV and radio transmission, voltage drop will reduce the quality of transmission and also cause the malfunction of other electronic components.

• Refrigerators are AC motor driven appliances that draw large currents during voltage drop conditions which may lead to overheating of windings.

• LED lamps failure rate increases at higher voltages.

To overcome above mentioned effects of voltage variations, voltage stabilizers are needed.

Types of voltage stabilizers

There are mainly two types of stabilizers – relay based voltage stabilizers and Servo Voltage Stabilizers/regulators. Relay based voltage stabilizers are typically single phase products used for low power applications (<5kVA) for television, refrigerator and air conditioners and they can provide voltage There are mainly two types of stabilizers - relay based voltage stabilizers and Servo Voltage Stabilizers/regulators. Relay based voltage stabilizers are typically single phase products used for low power applications (<5kVA) for television, refrigerator and air conditioners and they can provide voltage regulation from 230 volts±5%. The Servo Stabilizer is used for critical single phase and three phase applications from 1 kVA to 3000 kVA and can achieve precise voltage regulation of 230 volts±1%.

Servo Voltage Stabilizers and its applications

Servo Voltage Stabilizers

No electricity board in India can ensure constant voltage to the customers. Voltage is typically low during daytime and high during night hours. Moreover on holidays, peak hours, rainy days and when agricultural and industrial load is switched off the voltage arises sharply, which creates problems to the machineries resulting in financial loss.

90% of the industrial load consist of motors. In electric motors of smaller capacity up to 7.5 HP, during low voltage, the motor draws higher current which requires higher setting of overload relay to avoid the frequent tripping of motors. Higher setting of overload relay has very less safety margin against single phasing and mechanical faults. Suppose the relay setting is 15 to 20 % higher than actual operating current, then the relay will take 46 minutes to trip. The motor cannot withstand the high current for such a long time and in most cases, it burns out before the motor trip. Servo stabilizers are meant to overcome all the above problems by maintaining a constant level of voltage irrespective of the fluctuating mains power supply system

Servo stabilizer is a system, which provides stable Alternate Current (AC) output voltage where the input power supply voltage changes drastically. It protects the costly equipment from high and low voltage problems. It also increases the life of equipment’s and increases the productivity of machineries and reduces wastage and damage of raw materials by providing stable electric supply. The name Servo is related with the type of motor, which is used to enable the voltage correction (by using the Servo motor and variac with a buck-boost transformer.)

This type of stabilizer assures stable output power supply, protection from low voltage, high voltage, overload and short circuiting.

Applications of servo Voltage Stabilizers

The Servo Voltage Stabilizers are widely used in engineering units, pharmaceutical units, cold storage, air conditioning plants, offset printing machines, textile mills, cement plants, flour mills, oil industries, paper mills, rubber industries, tea estates, food processing units, oil and Vanaspati plants, footwear and leather units, distilleries and beverages, clubs, hotels, multi-storeyed buildings, hospitals, nursing homes, export houses and call centres.

Advantages of using Servo Voltage Stabilizers:

- protects the life of the equipment from severe voltage fluctuations.

- provides regulation with overall energy saving (98+% efficiency).

- no consumables are needed.

- improvement in quality of goods.

- increased production by reducing the manufacturing defective items.

- better safety and protection.

- fewer breakdowns and

- uniform quality of end products.

Components of Servo Voltage Stabilizers

Servo motor controlled automatic voltage stabilizer consists of following components

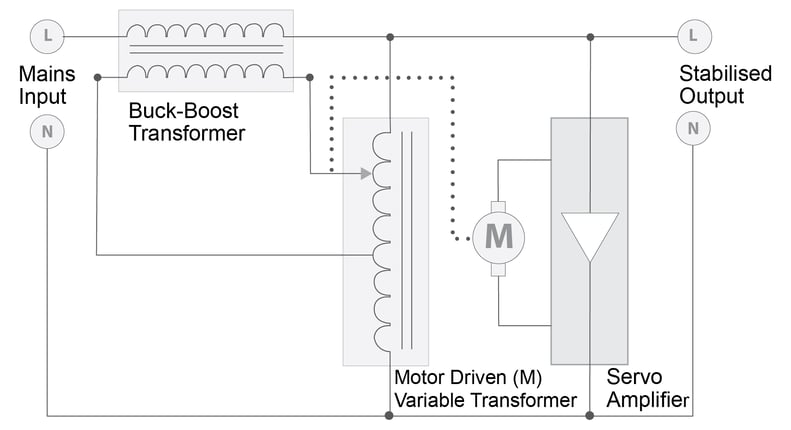

- Buck/boost transformer:

Buck/Boost transformer connected between mains input and output of stabilizer of load terminals. One terminal of primary of buck-boost transformer permanently connected to fixed tapping of auto transformer (variac) while another end connects to motor shaft.

- Auto transformer(Variac):

Autotransformer connected between neutral point and phase of input power supply.

- Motor

One end of primary of Buck-Boost Transformer connected to shaft of this motor with arm and brush mechanism. When motor moves then this arm shaft moves across winding of autotransformer to increase or decrease number of winding. Motor is generally AC Synchronous Motor or DC Servo Motor which is connected and it is fitted on top of autotransformers centre point.

- Motor driver

It is an electronic circuit which controls movement of motor. It consists of PCBs consisting of solid state circuitry made up of capacitor, registers, transistor, microprocessor and ICs.

Figure 1 Schematic of Servo Controlled Voltage Stabilizer

Working principle of Servo Voltage Stabilizers

Voltage received from mains at input of SCVS is continuously sensed by sensing circuit and gives feedback to main control circuit which consists of a microprocessor. This microprocessor continuously receives values of input voltages and compares with the reference value embedded in its program. Whenever there is high or low voltage at input of SCVS, the microprocessor gives trigger to motor driver.

Based on amount of high voltage or low voltage observed at input, “motor driver” moves servo motor across winding of autotransformer (variac) so as to increase or decrease the number of winding and hence voltage across primary of buck-boost transformer.

The Servo motor shaft is connected to primary of Buck-Boost transformer and when there is change in voltage across primary of buck-boost transfer, the induced voltage across its secondary also changes. The motor moves in such a way that proper voltage is applied across the buck-boost primary so that the output voltage should be equal to set or desired output voltage of Servo stabilizer.

This process takes place continuously so as to correct input voltages

In case of 3 Phase Automatic Voltage Regulator, there is an independent phase controlled unit for each of the three phases separately. (essentially) to check there are 3 number of Single Phase Servo Stabilizer in one three phase stabilizer.

China

China Europe

Europe France

France Hong Kong

Hong Kong Indonesia

Indonesia Japan

Japan Singapore

Singapore Thailand

Thailand USA

USA